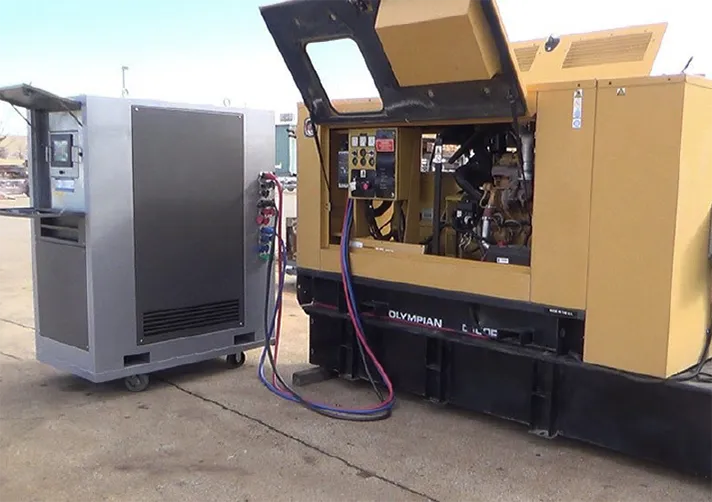

Engine Troubleshooting & Repairs

Engines are often the driver of many operations, whether by providing energy or running critical equipment. However, they are not immune to wear and tear and require regular maintenance and periodic overhauls. Addressing engine issues through consistent and regular maintenance, along with timely repairs is vital to ensuring peak performance, efficiency, and a prolonged and reliable operation.

The Foundation of Engine Repairs:

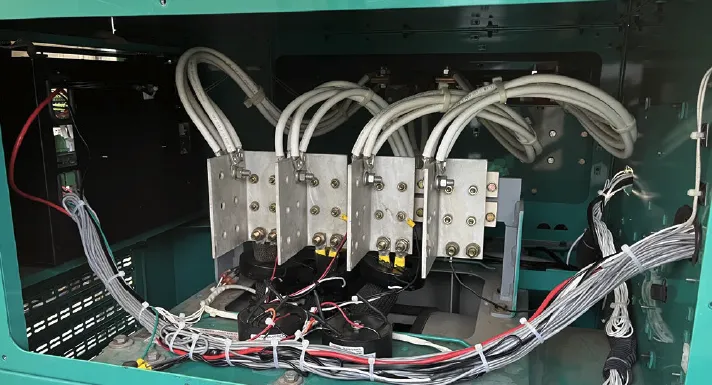

Accurate Diagnostics

Successful engine repairs begin with precise diagnostics. Modern engines are equipped with

advanced electronic control systems, which assist technicians in diagnosing issues. However, accurate diagnosis goes beyond reading codes — it requires the expertise of a skilled mechanic who conducts in-depth testing, including:

- Compression Testing:

Evaluates engine compression levels to identify potential issues such as worn piston rings, damaged valves, or faulty head gaskets. - Cylinder Leakage Testing:

Detects leaks in the cylinders to ensure proper sealing and diagnose potential problems affecting engine performance.

- Oil Pressure Testing:

Assesses the health of the lubrication system, ensuring optimal oil pressure for smooth and efficient engine operation. - Exhaust Gas Analysis:

Measures emissions to evaluate engine efficiency and identify areas for adjustment or repair.

Comprehensive Engine Repair Processes: From Maintenance to Major Overhauls

Engine repair encompasses a wide range of procedures, designed to address both routine maintenance needs and significant mechanical issues.- Oil and Filter Change: Regular oil changes are vital to maintaining engine health. Fresh oil provides proper lubrication, minimizes friction, and protects components from wear, ultimately extending the engine’s lifespan.

- Gasket and Seal Replacement: Leaks caused by damaged gaskets or seals can compromise engine performance and efficiency. Replacing these components promptly prevents further damage and maintains optimal functionality.

- Scheduled Overhauls: Most OEMs produce a maintenance schedule that contains recommendations for overhauls. In addition to the OEM recommendation, through preventative maintenance and condition monitoring, decisions can be made about the condition of your engine.

- Engine Rebuilding: For engines with extensive wear, rebuilding extends the life of the engine and improves performance. This process involves disassembling the engine, inspecting each component, and replacing or repairing worn or damaged parts to restore peak performance, bringing the engine back to OEM specifications.

- Cylinder Head Repair: Issues with the cylinder head, such as worn valves, valve seats, or camshafts, can impact air and fuel flow. Precision repairs ensure the engine operates efficiently and reliably.